The post Waterproofing Informations appeared first on Buyfromturkey.

]]>It necessary for the protection of concrete and reinforcements, which are the carrier systems of the buildings, from wear and corrosion. You should make waterproofing applications during the construction phase of the buildings. It primarily done in basements, garages and cellars of buildings. In other words, you should do it to the parts of the building that are under the ground. The most damaging substance to the building is water and humidity. The entire structure can damaged when the foundation of the building receives water or moisture. This isolation prevents the building from absorbing water and moisture. Waterproofing ensures that the building has a longer life and is resistant to water.

How Is Water Insulation Made?

You should do the waterproofing in the most appropriate way for the building. It is different for each building. Waterproofing provides nearly 100% protection while the foundation of the building laid. Some factors make waterproofing difficult later on. The first of these factors is that the building is old. That is, it has already been weathered by moisture and water. The second is that it is the adjacent building. Finally, due to factors such as the ground structure of the region, the waterproofing of the building can not completed or waterproofing can not done. For this isolation, some rules must followed first. If there is a water leak in the foundation, this isolation can only be done from the inside. This insulation does not prevent the building from getting water. It only protects the underground areas from moisture.

Suitable Surfaces

There are many areas of buildings that come into contact with water, which we call wet areas. Examples of these areas are foundation walls, terrace roofs, bathrooms, kitchens, or toilets.

Waterproofing minimizes water leakage in pools, prevents water leaks in wet places such as bathrooms and WCs, saves water in water tanks, and prevents spills in hidden streams, roofs, terraces, balconies, windowsills, and foundations, or exterior walls of apartments.

Why Is Waterproofing Important?

Soil absorbs water in precipitation, but when it is saturated with water, it can no longer absorb water and begins to give water. In today’s cities where there are buildings everywhere, it is not possible for the soil to absorb water anyway. That’s why we see that the parts of the buildings that are under the ground get water, there is moisture, and even flood in the rain. When the walls under the ground get wet, the carriers of the building are damaged. Exposure of the walls in the ground to moisture causes doubts in the soundness of the structure. Waterproofing is usually done on the lowest parts of the buildings, that is, in areas such as garages, cellars, warehouses, which are under the ground. For this, it is necessary to have waterproofing, especially when the building is still under construction.

Soil absorbs water in precipitation, but when it is saturated with water, it can no longer absorb water and begins to give water. In today’s cities where there are buildings everywhere, it is not possible for the soil to absorb water anyway. That’s why we see that the parts of the buildings that are under the ground get water, there is moisture, and even flood in the rain. When the walls under the ground get wet, the carriers of the building are damaged. Exposure of the walls in the ground to moisture causes doubts in the soundness of the structure. Waterproofing is usually done on the lowest parts of the buildings, that is, in areas such as garages, cellars, warehouses, which are under the ground. For this, it is necessary to have waterproofing, especially when the building is still under construction.

Benefits of Waterproofing

Waterproofing protects the building and helps make it stronger. The sections under the ground in the waterproofed building can not exposed to water and moisture. So it provides the foundation of the building. A solid foundation means a solid structure. Waterproofing offers comfort to the building. In the areas where waterproofing applied in the building, conditions such as mold can not encountered. This isolation increases the lifetime of the building. Thanks to the solid foundation this isolation, it becomes stronger and extends the life of the building. The benefits of waterproofing are basically to protect the building.

The post Waterproofing Informations appeared first on Buyfromturkey.

]]>The post Briquette – Light Weight Building Material appeared first on Buyfromturkey.

]]>Concrete briquettes contain filling materials such as sand, gravel, tuff slag, sifted boiler slag, brick and tile fragments, pumice (pumice stone). These materials mix with cement and water in a moist consistency. They are formed by forging, pressing, or vibrating in special molds.

Briquette walls made of sand and gravel are heavier than others. On the other hand, they are more resistant to load and weather conditions. The borders with pumice are mostly preferred because they are more successful in lightness and sound, and heat insulation.

The unit volume weight of the concrete to be produced with the product should not be more than 1600 kg/m³. They are more economical than other wall elements. Plug-in products eliminate the need for mortar. Therefore, it provides advantages in terms of time, labor and cost. In addition, having a high degree of thermal insulation properties reduces fuel consumption compared to bricks. Sound insulation properties are 50% higher than brick blocks. Since it does not contain any material other than cement, pumice, and water in its structure, it does not pose a danger to human health. The walls provide the moisture balance of the environment due to their porous structure and allow the building to breathe.

Weight of Briquette

Single-row -800 kg/m³

Single-row -800 kg/m³

Two-row -9000 kg/m³

Three-row – 1000 kg/m³

Hollow block- 700-900 kg/m³

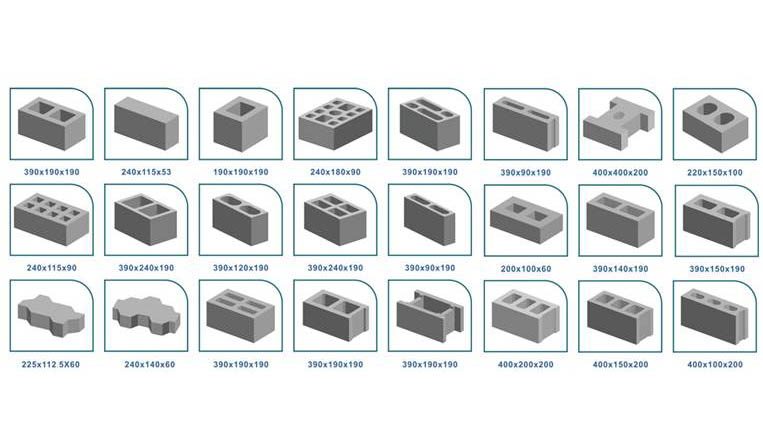

Briquette Dimensions

Manufacturers either solid or hollow, with mortar slots on the sides. Its dimensions are usually 6 x 11 x 23, 10 x 20 x 40, 20 x 20 x 40 and 20 x 30 x 40 cm. The tolerance in dimensions should not be more than +-3mm in all dimensions and also +-2mm in tapers or slopes.

The wall thickness between the holes and the edges should not be less than 3 cm in perforated briquettes, which generally made with two holes, and five sides are closed, and one side is open. In addition, the total of the hole volumes should not exceed 50% of the book.

Advantages of Briquette

- Briquette is the cheapest among light insulation materials.

- Its very low thermal conductivity coefficient provides high thermal insulation.

- In buildings, window sizes can enlarged, and wall thicknesses can reduced.

- Porous internal structure provides sound insulation and sound absorption.

- It is much lighter than materials with the same volume and properties produced with normal aggregates.

- Its smooth surface saves labor and plaster.

- Compressive strength is high (25 – 70 MPa).

- Freeze-thaw resistance is high.

Thermal Insulation Properties of Briquettes

Briquette elements have excellent thermal insulation properties due to their low unit weight and porous structure. The fact that the pumice aggregates in its structure contain many homogeneously distributed tiny pores considerably reduces the thermal conductivity coefficient. As a result, fuel consumption decreases, window widths in buildings can increased, and wall thicknesses can thinned.

Sound Insulation Properties of Briquettes

Briquettes have good sound insulation properties thanks to the homogeneous cavities they contain, their low unit weights, and the absence of crystalline pore water. These features also cause sound waves to dampen the surfaces of the elements produced with the product. Thus, it provides good sound insulation and acoustics.

Moisture and Vapor Permeability

Briquette plays an essential role in maintaining the moisture balance of the environment due to the pumice aggregates. When the ambient humidity rises, it traps some of this moisture in its structure and balances the environment. In the same way, the decrease of ambient humidity gives excess water to the environment. The pore structure of the product contains independent spaces from each other, and the pores it has are insulated with a membrane, so it does not hold water and water vapor.

Fire Resistance

In the briquette production processes, no organic material used in the structure. It also known that the pumice aggregates used in the production do not contain organic matter. For this reason, it operated as wall elements during any fire that do not burn, do not cause glare, and do not create smoke.

The post Briquette – Light Weight Building Material appeared first on Buyfromturkey.

]]>The post What is Bims (Pumice)? appeared first on Buyfromturkey.

]]>Our country has 9 billion m³ reserves in the Central and Eastern Anatolian Regions. Especially the beds in the Nevşehir region are above world standards in terms of quality. Bims, obtained from licensed fields in Nevşehir or other open pits, classifies the pumice as raw material and uses it as raw material.

History of Bims in the Construction Industry

We know that Bims was first used as pozzolan cement in the construction sector, as it was in the dome of Hagia Sophia during the Roman period. It started to used in the production of light building materials in Germany in 1851. In Turkey, the first production of professional lightweight construction elements started in Nevşehir in 1984. Today, it has become popular in many countries due to its lightness, naturalness, economy, resistance to earthquakes and fire. For these reasons, it is a preferred material for heat and sound insulation.

We know that Bims was first used as pozzolan cement in the construction sector, as it was in the dome of Hagia Sophia during the Roman period. It started to used in the production of light building materials in Germany in 1851. In Turkey, the first production of professional lightweight construction elements started in Nevşehir in 1984. Today, it has become popular in many countries due to its lightness, naturalness, economy, resistance to earthquakes and fire. For these reasons, it is a preferred material for heat and sound insulation.

Lightweight Construction Elements

After the first production of light construction elements in Nevşehir in 1984, various facilities started to operate. Despite all its advantages, the producers carried out promotional activities to know that pumice is not well known in our country. Thus, they introduced bims and popularized its use. Afterward, pumice became widespread as interior and exterior wall building elements in all kinds of structures and as a hollow block in floors.

Features of Bims

It is heat and sound insulated. Bims, used as the raw material of lightweight construction elements, naturally provide heat and sound insulation.

It is heat and sound insulated. Bims, used as the raw material of lightweight construction elements, naturally provide heat and sound insulation.

It is earthquake-resistant. Since pumice is a material with high elasticity, the building elements produced from pumice have more strength than other building elements. (The elasticity coefficient against breaking due to earthquake waves is 70.000 kg/cm2.) Since it is six times more flexible than concrete, it can absorb shocks more easily without breaking or cracking and provides resistance against earthquakes.

It is economical. Masters plaster the interior walls directly with gypsum plaster. While building walls in constructions, rough and fine plaster needed on walls made with other building elements; it is sufficient to apply a single layer of plaster on pumice exterior walls. In addition, less plaster is enough since it has a smooth surface. Since the surface of the products is smooth and decorative, it is possible to use them without plastering.

It is fire-resistant. We know that Bims, which has a high melting temperature, is highly resistant to fire. (It has the feature of not catching fire for at least 239 minutes at 1100°C combustion temperature, not losing shape and size, and not emitting smoke.) Pumice with a high melting temperature minimizes the damages of fire since it does not emit any gas harmful to the environment when melted.

It is natural. It balances the ambient humidity. Since pumice contains a high amount of water vapor, it prevents moisture. In addition, due to its porous structure, it makes natural ventilation into the space, creating breathing, odor-free and healthy spaces.

It is environmentally friendly. Since pumice produced only with vibration energy, the required energy requirement is shallow. Since no chemical or biological technique used in production, there is no waste. Moreover, no danger threatens workers’ health.

It is light. One of its most important advantages is that it is lightweight due to its porous structure. The product with a specific weight of 0.6 kg/dm³ is lighter than other building products, thus reducing the load on the building foundation.

The post What is Bims (Pumice)? appeared first on Buyfromturkey.

]]>The post Aerated Concrete Usage Areas appeared first on Buyfromturkey.

]]>Aerated Concrete Thermal Insulation Board

Thermal insulation board is a wholly mineral-based and non-combustible thermal insulation material. It is one of the most preferred products in Europe for thermal insulation. It ensures that the energy loss minimized.

Aerated concrete thermal insulation board provides excellent thermal properties that keep the heat outside in hot weather and inside in cold weather, and small pores in its structure filled with stagnant air. It also offers high thermal insulation performance with a thermal conductivity calculation value of 0.044 W/mK. It does not lose its thermal insulation property and durability throughout the life of the building.

Thermal insulation board is 100% safe against fire. It classified as “A1 class non-combustible” building material. It provides absolute safety in case of fire, does not emit any toxic gas or smoke even at the highest temperatures. With the aerated concrete thermal insulation board, facades and thermal insulation solutions under fire regulations can formed safely without taking additional precautions, including high-rise buildings, without risk of fire.

Aerated concrete insulation board is completely mineral-based and also open to water vapor diffusion. It does not carry any biological and microbiological defects. Breathing walls provide a healthy living environment in the building by preventing the formation of moisture, mold, fungus, and microorganisms that affect the comfort of life. Even when wet, its durability does not decrease. So, it creates a comfortable indoor environment by providing a balanced temperature and humidity level in the building.

The thermal insulation board produced from natural materials such as sand, lime, cement, and water. It does not contain any substances that cause environmental pollution and are harmful to human health. Fully recyclable.

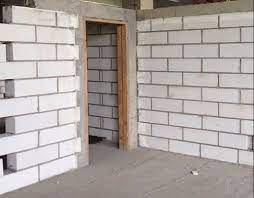

Wall Blocks

They used as external and internal filling wall material in building systems such as reinforced concrete, steel, wood, and prefabricated, or as a load-bearing external and internal wall material in masonry structures. They are the most preferred building materials in the construction of firewalls.

They used as external and internal filling wall material in building systems such as reinforced concrete, steel, wood, and prefabricated, or as a load-bearing external and internal wall material in masonry structures. They are the most preferred building materials in the construction of firewalls.

Aerated concrete wall slabs produced in 60 cm length, 25 cm height, and various thicknesses. According to the forehead profile structure; They divided into Single Plug, Double Plug, and Straight wall blocks.

Aerated Concrete Roof Plate

However, it is a building material and a ready-to-assemble building component that can fulfill the versatile properties obtained with the combination of more than one material.

Aerated concrete roof slabs can offer carrier, long life, fire safety, sound insulation, openness to diffusion, and above all, high thermal insulation. Roof elements can applied in any type (flat or pitched roof), any shape (such as gable roof, hipped roof, shed roof), and any roof covering (such as ventilated-cold roof or non-ventilated-warm roof).

Floor Plate

They are ready-to-assemble building components. The said elements have a maximum carrying capacity at the time of delivery. Floor slabs, which can be produced in various thicknesses and also lengths, allow floors with different bearing capacities.

Aerated concrete floor slabs contribute to the rigidity of the building as they can also meet horizontal loads if a suitable application made. They are load-bearing structural elements used to form roofs or floors on wooden, concrete, or steel supports of masonry and carcass structures.

Pocketed Light Holster

It is a light filling material for reinforced concrete hollow blocks. Pocketed Light Hollow Hole allows the production of light, earthquake resistant, and economic constructions like other aerated concrete products.

Hollow filler increases building comfort by providing sound and heat insulation on floors. Due to its easily cut structure, it does not create wastage in the application. Due to its void-free structure, Pocket Hollow Filler, which does not fill with concrete, provides concrete savings of up to 15% in floors. Thanks to the smooth surface formed on the flooring, it also saves 30-40% plaster.

Aerated Concrete Jamb

They have reinforced building elements used to provide architectural aesthetics on the edges of doors and windows. According to the project, these non-bearing elements are produced in any desired length and in a wide variety of shapes. Furthermore, jambs easily mounted on walls and lintels with aerated concrete mesh glue and various fastening systems.

The post Aerated Concrete Usage Areas appeared first on Buyfromturkey.

]]>The post What is Concrete and How is it Produced? appeared first on Buyfromturkey.

]]>Concrete is a widespread building material today. There is almost no construction that does not require concrete. It used in the construction of roads, buildings, bridges, other structures, and water structures such as dams and canals. This product appears both as a carrier element and as a decorative material. It preferred in durability, fire resistance, water resistance, economical production, energy efficiency, and on-site manufacturing. This product also used in making ready-made reinforced concrete products.

Concrete Production

Separate industrial branches prepare the cement and aggregate required for concrete. The last step is to prepare the mixture and use the concrete. Selection of appropriate mixing ratios; It ensures that properties such as economy, machinability, strength, durability, and appearance obtained in a balanced way. These vary depending on where they used. The ratio of mixing water to cement amount is the most critical factor affecting the strength. Another crucial factor is the amount of air in the product. This amount is around 0.3-3% in standard concrete. These two effects constitute the two most essential factors in the control of product quality.

Separate industrial branches prepare the cement and aggregate required for concrete. The last step is to prepare the mixture and use the concrete. Selection of appropriate mixing ratios; It ensures that properties such as economy, machinability, strength, durability, and appearance obtained in a balanced way. These vary depending on where they used. The ratio of mixing water to cement amount is the most critical factor affecting the strength. Another crucial factor is the amount of air in the product. This amount is around 0.3-3% in standard concrete. These two effects constitute the two most essential factors in the control of product quality.

It is also essential to obtain a homogeneous concrete mixture. Mixing work carried out with concrete mixers at the construction site. In some exceptional cases, they also do the mixing with shovels. In general, they measure the cement bag, aggregate weight, and water volume, which make up the mixture. Some producers prepare the mixture. In return for the request to made here, they prepare a ready-to-use combination of the desired quality. Mixing can done in stationary mixers as well as in mobile mixers.

Hardening

The last step in obtaining concrete is the maintenance and hardening of the poured the product. Hydration of hardening portland cement, chemical reaction with water

We generally think that concrete hardens as a result of the evaporation of water. In reality, this is not true. Without water, neither hydration nor hardening can take place. The water lost due to the hydration of the cement and only allows the excess water to evaporate. Chemical reactions in the circuits of this are pretty complex.

Producers now use additives due to the problems occurring in the concrete produced. These additives both increase the strength of the product and protect it from water damage, and allow the admixture to be fluid or solid according to its consistency.

Durability

Concrete durability is its resistance to aggressive elements in the external environment. In addition to these elements, it is possible for the components that make up the product to react in some cases. Such internal corrosion events can exacerbated depending on the external environment. It must be resistant to natural chemical damages and not lose its qualities due to external physicochemical factors. For this, producers want to have sufficient chemical resistance (durability).

Concrete durability is its resistance to aggressive elements in the external environment. In addition to these elements, it is possible for the components that make up the product to react in some cases. Such internal corrosion events can exacerbated depending on the external environment. It must be resistant to natural chemical damages and not lose its qualities due to external physicochemical factors. For this, producers want to have sufficient chemical resistance (durability).

As a result of the reaction of any element made with cement, its strength should not increase over time but should not decrease. It loses its potency over time due to a number of chemical reactions under various harmful effects. In this case, the structure is partially or wholly destroyed or becomes unusable due to not being able to withstand the forces to which the product is exposed. Carbonation, which is a physicochemical process, decreases the alkalinity of the environment and destroys the protective oxide layer.

The post What is Concrete and How is it Produced? appeared first on Buyfromturkey.

]]>The post PVC Windows Advantages appeared first on Buyfromturkey.

]]>Compared with aluminum or wooden windows, PVC Window insulation value is the best product. Therefore, they can reduce energy and heating costs. Especially when using these products in passive house standards, very high energy saving potential emerges. Today, inactive house windows can produced efficiently and cost-effectively using state-of-the-art PVC profiles and triple glazing.

PVC windows are longer lasting than windows made of wood. High-quality PVC windows have maintained their first-day performance for years with their deterioration resistance and functionality levels. PVC windows are an excellent investment to protect the value of your property.

What is the Difference Between Pvc Joinery and Aluminum Joinery?

PVC Joinery is more affordable than aluminum joinery. In PVC, low air is less likely to get in. There is a possibility of penetration in aluminum. PVC is more advantageous in terms of thermal insulation. It passes the heat more difficult. In terms of aesthetics, PVC has more color and pattern options. Both are of good quality. However, if it uses poor quality, it isn’t easy to be satisfied. Since it produced from PVC plastic, it is easier to recycle than aluminum. PVC is lighter than aluminum. It may not be as successful as aluminum at low and high temperatures. It is used in the manufacture of windows and doors, reducing tree cutting and helping to protect forests. In addition to the high ignition temperature of PVC, it can extinguish itself when ignited.

Cost/Benefit Ratio of PVC Windows

PVC windows provide a net cost advantage both in the first purchase and throughout the product life. Wooden windows are about 20-50% more expensive than PVC windows, while Aluminum windows cost 30-70% more as the most costly alternative. Based on its high energy saving potential and minimum maintenance over a service life of more than 50 years, it is the most economical alternative in the short and long term.

Care

High-quality PVC windows require little maintenance and are extremely easy to maintain. On the other hand, wooden windows should be varnished every two years and painted every five years. State-of-the-art PVC raw materials are very resistant to all weather conditions. Bleach-free dishwashing liquid is sufficient to clean smooth Window frames.

Fire Resistance

PVC windows using in buildings, other plastics, wood, textiles, etc. Due to the high chlorine content, PVC windows have fire safety properties. Like organic substances, it will burn when exposed to fire. However, hhese products are self-extinguishing, meaning they stop burning if the fire source removed. It is challenging to ignite; the heat generation is relatively low.

Eco-Friendly

PVC windows are 100% recyclable and therefore save resources. 40% of the world’s gas and oil reserves are used for heating and energy supply to buildings, only 4% for all kinds of PVC raw materials, and only 1% of this rate is used to produce plastic windows. In addition to being recyclable, the low pollution levels during the production of PVC profiles cause minor damage to the ecological balance than wood and aluminum and contribute to the protection of the environment. These products are much more durable than wooden windows and consume significantly less energy during the production process. The PVC content can degrade, and the granules can be processed for regeneration and recycled at least seven times. (The carbon footprint of the PVC window profile is 248.8 kg CO2, the carbon footprint of the Aluminum window profile is 485.9 kg CO2)

PVC Windows Are Safe

PVC is non-toxic. It is a safe material that using for over half a century. These product is also one of the most researched and thoroughly tested raw materials in the world. It complies with all international standards in terms of safety and health, both for the products and applications used.

The post PVC Windows Advantages appeared first on Buyfromturkey.

]]>The post Turkish Construction Industry and Its Development appeared first on Buyfromturkey.

]]>Significant shares are taken in the areas of added value, employment, and production created. Export and foreign exchange earning services constitute one of the essential elements of the sector. Commercial activities such as export of construction materials, overseas contracting and consultancy services, real estate sales to foreigners are also developing in Turkey. Many factors such as mega public projects, urban transformation, and infrastructure investments accelerate the construction sector. In this context, it is crucial to produce data on the construction industry and the construction materials industry both in the world and in Turkey.

Development of the Turkish Construction Industry

The Turkish Construction Sector, primarily based on the national capital, has a significant impact on the employment and production process as it concerns hundreds of professions. The sector, which has excellent experience and potential in the national and international fields, is the ‘locomotive sector’ to activate more than 200 sub-sectors connected to it. It is also the ‘sponge sector’ as it is an important source of employment. Its share in GNP is around 30% with the contribution of other sectors that provide input to the sector and continue their activities depending on the developments in this sector.

The construction sector in Turkey has shown severe development since the 1980s. In the 1993-2003 period, there was a contraction in the construction sector. Housing Sector has started to revive since 2004. In the first half of 2005, the rate of increase in building permits increased by 40% compared to the same period of the previous year.

In addition to these, Turkish Contractors have realized around 5000 projects in 70 countries since the early 1970s. Their total cost is around 130 billion USD. At the same time, companies that build detached houses designed to meet all the needs of their customers have also increased in the sector in recent years. One of the best quality examples of these companies is Bahçeli Müstakil Ev.

Turkey Sectoral Data

The construction sector was among the industries that were adversely affected by the epidemic. On the other hand, growth was observed in the real estate sector despite the effects of the epidemic. Total construction expenditures increased. At the same time, complete building permits increased based on area. In parallel with this, residential building permits and non-residential building permits have also increased on a field basis. In the same direction, there has been an increase in house sales.

Housing Sector

The housing sector continues to be the most important field of activity for the construction sector and the construction materials industry. In this framework, multidimensional and detailed indicators and evaluations regarding the housing sector are included. While the housing sector was a drag in the construction sector in all aspects in 2017, it shrank in 2018 and 2019. In 2020, with the support provided, the housing sector had a significant growth.

Housing sales increased in 2020 compared to the previous year. The epidemic in 2020 and the support given to the housing sector affected housing sales in two different ways. In the second quarter of the year, there was a significant decrease in house sales due to the epidemic. The support given to the housing sector, on the other hand, started to show its effects as of June. Low-interest housing loan campaigns significantly increased the housing demand, especially in the third quarter. Housing sales increased rapidly.

Source: Turkey IMSAD Building Sector Report.

Companies of Turkish Construction Industry

Many Turkish names are among the largest construction companies in the world. This list preparing according to the volumes of the businesses abroad. There are 46 companies from Turkey in the “World’s Top 250 International Contractors” list. Examples of these are companies such as Renaissance Construction, Limak Construction, Tekfen Construction and Installation.

If you want to learn more about other news in Turkey, you can visit our website.

The post Turkish Construction Industry and Its Development appeared first on Buyfromturkey.

]]>The post Painting a House Tips appeared first on Buyfromturkey.

]]>Colour Selection

There are several different criteria to help you determine the colour choice. It would help if you chose according to the physical characteristics of the room you want to paint, the colours of your furniture and finally the current trends. There are no strict rules on colour selection when painting a house. The choice is entirely up to your taste.

Paint Selection

There are quite a few different types of paint for interior facades. You should choose the one that is suitable for your walls among the types with features. Each different colour has its unique advantage. Regardless of the type, we strongly recommend that you choose quality paint. It painted with good coverage of quality lacquer.

Before you start painting, you should decide which wall to paint which colour and calculate how much paint you need. If you choose different colours for different walls, you have to figure one by one. Whether you paint your entire house or some of its walls, we recommend that you buy a little more paint than you calculated.

Necessary Materials for Painting A House

Materials needed for the paint: Of course, the colour of your choice, the nap brush, the paint roller (for 20), the mini roller, the paint grid, the paper tape, a large pail and a sturdy stick for mixing the paint, a ladder to reach the tops and covering the floor comprehensive plastic covers. For lining, primer suitable for paint, brush, fine sandpaper, cloth. Suppose there are cracks in the wall; putty/plaster, spatula, sandpaper.

Protection of Household Goods and Floors

Before starting the painting a house process, you should completely open the front of the wall you want to paint. If you are going to sandpaper, you should cover your furniture and other items. Also, be sure to cover the floor with wide plastic sheets due to the possibility of paint dripping onto the floor.

These thin covers sold at affordable prices in paint shops and DIY stores. If you can’t find it, you can also cover it adequately with newsprint. In any case, it would make sense to secure it with paper tape so they wouldn’t move, whether it was a sheet of newsprint. It is also vital to mask baseboards, door and window frames, and cover them with paper tape, to ensure things are safe. You can remove the sockets and electrical switches and reassemble them after the painting process is finished.

Painting a House Process

Before painting your walls, you should make the wall suitable. For this, you need to prime. The lining has many functions. These are to make the surface smooth, reduce the paint consumption by reducing the surface’s absorbency, and ensure that the paint adheres well to the surface. In addition, since the surface becomes homogeneous, the covering property of the paint increases. Different primers sold in the market, and the primer to be used before painting must be suitable for the paint to be applied on it.

It would be best if you started by mixing the water-based paint of your choice with enough water. This ratio will differ from colour to paint, and the necessary instructions are on the colour can. If you make a particular colour mix, do not forget to get this vital information from the person who made the mix. Next, you have to do the fine details and cuts. Then you can continue the process by painting your walls. After the paint dries, you can paint the second coat according to the rate of covering the wall. Finally, it would help if you waited for the paint to dry thoroughly.

Also, if you are going to paint your ceilings, you should paint your wall before painting. Otherwise, the ceiling paint may flow on your wall paint and disrupt your process.

The post Painting a House Tips appeared first on Buyfromturkey.

]]>The post Exterior Ceramic Models and Features appeared first on Buyfromturkey.

]]>Exterior Ceramic Models

Exterior ceramic models produced with similar qualities to the ceramics we usually use in our homes. However, the surface coating called glaze may be different. This glaze part is the part where the strength of the ceramic is determined. For this reason, if it is specified that it is a suitable product, you can apply the ceramic models you have applied for indoor use on your exterior as well. For this reason, some companies produce ceramics that you can use both indoors and outdoors. You should pay attention to this feature when choosing your Ceramic.

Exterior Ceramic Features

Exterior ceramic properties are superior to other wall covering panels and types. Suppose you have an exterior cladding solution in mind. In that case, we recommend you examine the types of ceramics that can cut moisture, humidity and noise to a great extent and show maximum resistance to these external factors. Ceramic models are pretty durable. And basically, its production is made from soil.

Ceramic obtained by firing clay soil. Ceramic, which fired in ovens of thousands of degrees, is a natural material. The process applied to take the final shape of the ceramic surface called glazing. Glaze increases the water, heat and good resistance of the ceramic surface; it adds texture to ceramics.

Ceramic is an inexpensive material. It is much longer-lasting and more affordable than the alternative wall covering panels and types. Ceramic is a product that can impress everyone with its designs. It can be used in all kinds of environments. There is a ceramic model for all tastes in terms of design.

In short, these are the most important reasons why exterior ceramic models and types have become so popular and preferred in many new residences and buildings. In addition, when the worldwide ceramic production is examined, it can be seen that the ceramics produced in Turkey are pretty successful and are exported to many different countries.

Which Ceramics Can Using on Exterior Facades?

Ceramic is a product obtained from firing the soil and produced from specific materials in primary production techniques. The ceramics we use in our homes and the ceramics used on the exterior of buildings are very close. If you are going to apply ceramic coating but cannot find a suitable ceramic for yourself as exterior ceramic models, some interior ceramics will also work. But here, it is necessary to consult a specialist. Exterior ceramic models are specified in various product catalogues. Most ceramics you use in your interiors, bathrooms or receptions are also suitable for outdoor use. However, a successful ceramic coating application required for outdoor use.

Consider These When Choosing Ceramics

For terraces or facades, choose ceramics with low water absorption coefficient on surfaces exposed to outside weather conditions. Especially porcelain tiles are more suitable materials for cold weather conditions.

Take care to use wall tiles on the wall and floor tiles on the floor. Because with floor tiles, you may cause a load that is too heavy to carry on the wall. Keep in mind the necessity of using the suitable adhesive as well as choosing the right tile. The dimensions and form of the place you will apply will also determine your colour choice. Choosing the right size is as important as deciding on the style and colour of the tiles.

After taking the dimensions of the surfaces, it is necessary to decide whether the tiles will be square, rectangular or in another form. In which direction you want to make the space look long or wide, place the long side of the rectangular tiles in this direction.

You can increase the sense of depth by covering a wall with a darker colour tile in spaces where you can make it appear larger by using light tones. You should prefer tiles with matte and non-slippery surfaces, especially in places where small children run around and where safety is a leading criterion. These products are also easy to clean.

The post Exterior Ceramic Models and Features appeared first on Buyfromturkey.

]]>The post All About Best Air Purifiers Products appeared first on Buyfromturkey.

]]>We spend around 80% of our time in closed rooms. This is not without consequences for our health: numerous studies report a high level of indoor air pollution. There are several ways to improve indoor air quality, and the most effective is arguably the air purifier. However, this is an expensive purchase. To choose the best purifier, we invite you to consult our article.

What is an air purifier?

An air purifier is a mobile device designed to clean the indoor atmosphere. It is equipped with several filters which capture airborne pollutants, in particular, fine particles responsible for many allergies and which cannot be removed by a vacuum cleaner. The goal is, therefore, to get rid of anything that can affect our health. Cleaned and purified air contributes to our well-being. Improving air quality is particularly crucial for frail people, such as young children and the elderly. The air purifier can be taken from room to room to sanitise the entire house.

How does an air purifier work?

The principle of this device is to treat all airborne impurities. Because they come in a variety of sizes, air purifiers are usually equipped with several types of filters. The number and specificity of these filters dramatically affect the performance of the unit.

The first filter, also called “pre-filter”, aims to capture macro-residues: those that can be seen with the naked eye and which measure a few millimetres (hair, animal hair, threads or coarse dust). The purpose of this pre-filter is to provide better performance for the following filters designed to trap fine particles that are more harmful to our respiratory system. For better efficiency, the purifier must be equipped with several filters. The role of the HEPA filter is to filter particles with a diameter of less than 0.3 µm2. To pass certification tests, it must destroy at least 99.97% of these particles.

The purifiers which are equipped with it obtain the best results in the tests and the comparison of products. Those who are often successful in tests are also equipped with a carbon filter. This eliminates odours, chemicals and gases, which the HEPA filter cannot. At the end of the treatment, the sanitised air is released into the room.

Advantages and fields of application.

The main advantage of an air purifier is that it makes the air more breathable, especially for allergy-sensitive people. This device is particularly recommended for purifying the air breathed by young children, the elderly or sick people. People with dust mite, dust and micro-mould allergies who use an air purifier usually see a rapid improvement in their condition.

Many places with a high-risk public are equipped with purifiers: Hospitals, nurseries, swimming pools or retirement homes are places where the benefit of an air purifier is felt. This device can also be found in workshops where employees are particularly exposed to micro-particles.

What types of air purifiers are there?

There are five main types of air purifiers. This is an essential factor to take into account when comparing different types of devices. If you consult a comparison before making your purchase (which we advise you to do), remember to check that the nature of purification is clearly specified in the comparisons

Ionisation or electrostatic air purifier

The principle is based on the soothing and energising effect of negative ions or anions. They are the ones you find in the forests or by the sea. The ioniser generates a number of ions in the interior.

Polluting particles, which are positively charged, are automatically attracted to the anions. Little by little, they become more substantial and fall back into the aircraft or onto the ground.

Advantages :

Economical.

Fast.

Quiet.

Efficient for microscopic particles.

Disadvantages:

It does not destroy: so you also have to vacuum and clean the floor.

The air purifier with filtration

As said above, the HEPA filter is a high-performance filter that retains extremely fine particles. It is beneficial in trapping dust mites, pollen, ultrafine dust or combustion residues.

Since it does not treat chemical or gaseous substance, this filter is usually accompanied by a carbon filter. In the field of air purifiers, This combination of filters achieves the best results, both when considering user opinions and comparative tests.

Advantages :

The captured pollution remains in the filter: so it is well removed from the room.

Disadvantages:

The technique requires the use of ventilation, which can be noisy. This is a crucial point to consider. Filters need to be changed regularly to remain active.

The plasma air purifier

Its technology is reminiscent of ionisation: it consists in exciting the oxygen in the air to generate molecules that are propelled into the room to attack pollutants. Charged, these are collected in a cartridge inside the device. Plasma damages the walls of viruses and bacteria, making them ineffective.

Advantages :

Eliminates bacteria and viruses.

Disadvantages:

The released molecules clog the air with harmful free radicals. The technology should, therefore, be reserved for rooms that are not visited continuously.

The photocatalytic air purifier

This type of air purifier is equipped with a catalyst tube often coated with titanium dioxide.

Under the action of the light projected onto the catalyst, the pollutants are oxidised, neutralised and transformed into water and carbon dioxide.

Advantages :

Quiet.

Destruction of biological and chemical pollutants.

Disadvantages:

Risk of free radical release.

Light source compulsory.

The combustion air purifier

The air that enters this air purifier is heated to 200 ° C, which destroys all pollutants, including viruses. It is then cooled and reinjected into the perfectly purified room.

Advantages :

Quiet.

Requires minimal maintenance.

Disadvantages:

Long processing.

High power consumption.

What should you pay attention to when purchasing an air purifier?

It is essential to define your needs and not necessarily select the air purifier that wins the comparison if its characteristics are not adapted to your needs. You must determine the surface to be purified and not choose a model that is too small or oversized. Noise level, size and weight are also criteria to look at carefully to make the best choice.

Air purifiers do not necessarily treat all types of pollutants, so make sure it meets your needs.

Alternatives to the air purifier

If this is often the best solution; purchasing an air purifier is not the only way to solve the problems caused by indoor pollution. The installation of a centralised suction system, which removes fine particles, can be considered when building a home. The device is relatively expensive but very efficient.

Another alternative is to use natural solutions. To renew the air, make sure to ventilate the interior for at least 10 minutes morning and evening. The best way to eliminate toxins is to keep them out of the house.

The use of natural household products and the elimination of indoor air fresheners contribute to maintaining a better atmosphere. Essential oils with antibacterial, antiseptic or antiviral powers can also be an alternative to air purifiers.

If you wish to buy air purifiers from Turkey, please do not hesitate to contact us by mail at [email protected] or to call us at +90 532 361 5149. We can help you to get in direct contact with producers or provide you with everything that you need.

Please visit the company website for more information about their products. If you want to know about companies in Turkey, visit our website.

The post All About Best Air Purifiers Products appeared first on Buyfromturkey.

]]>